Welcome!

No matter who you are or where you are on life’s journey, you are welcome here!

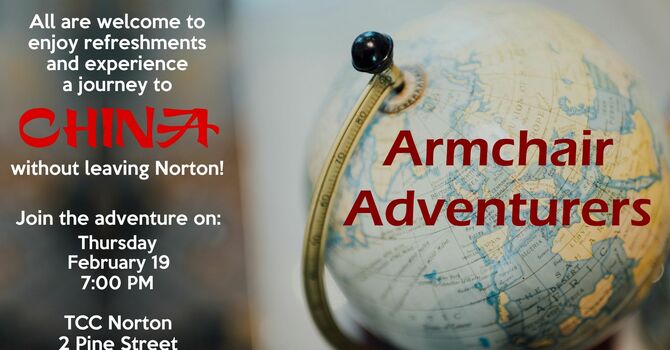

Welcome to TCC Norton!

Trinitarian Congregational Church

Please feel free to browse our website, visit us during our Sunday morning worship or Thursday office hours, or send us a message on our Contact page. We look forward to seeing you!

Latest News

Recent updates to keep you in the loop.